In the intricate world of nature’s materials, spider silk stands as a marvel of engineering. Gossamer-thin yet possessing strength that rivals industrial metals, this remarkable substance has captivated scientists and engineers for decades. While steel has been humanity’s go-to material for strength and durability since the Industrial Revolution, the humble spider produces silken threads that, pound for pound, outperform this metal champion. This natural wonder combines extraordinary tensile strength with remarkable flexibility and resilience—a combination that human-made materials struggle to match. As we face growing challenges in sustainability and resource limitations, spider silk offers tantalizing possibilities for revolutionary materials that could transform industries from medicine to aerospace. Let’s explore the fascinating science behind spider silk’s surprising strength and the cutting-edge efforts to harness its potential.

The Remarkable Composition of Spider Silk

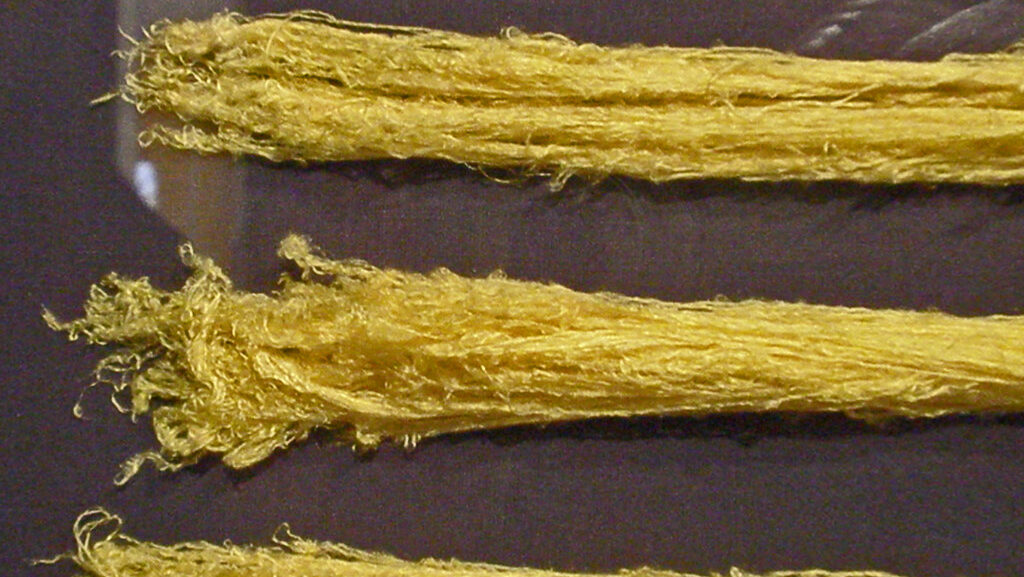

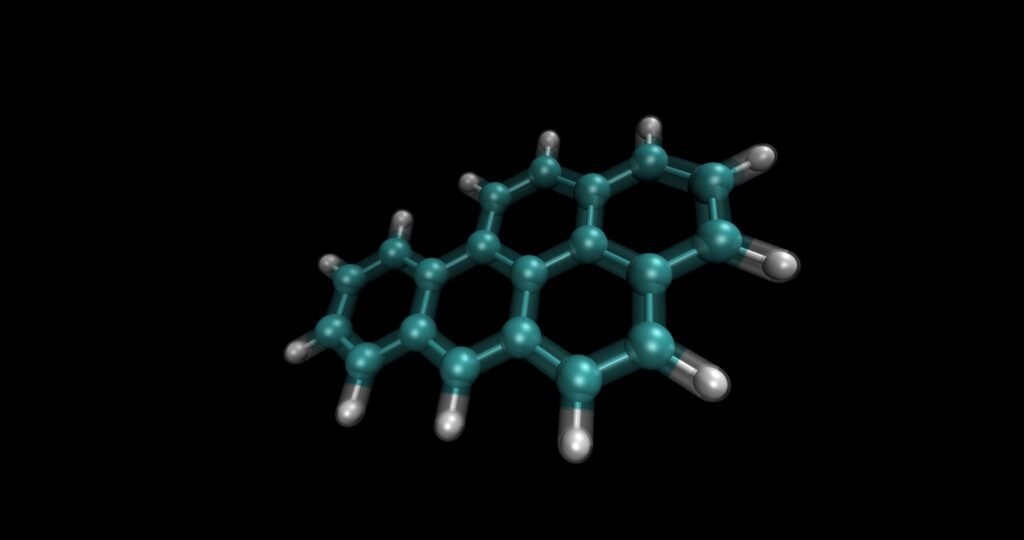

Spider silk is fundamentally a protein-based fiber composed primarily of fibroin, a structural protein with a unique molecular structure. Unlike the rigid crystalline structure of steel, spider silk proteins fold into a combination of rigid crystalline segments connected by more flexible amorphous regions. This protein arrangement creates a natural composite material where the crystalline portions provide strength while the amorphous sections allow for flexibility and elasticity. The silk proteins contain numerous hydrogen bonds that, while individually weak, collectively create tremendous strength through their sheer quantity. Additionally, the spinning process itself contributes to the silk’s strength as the spider draws the liquid protein solution through specialized glands, causing the proteins to align and form stronger connections as they solidify into fibers.

Comparing Strength: Spider Silk vs. Steel

When comparing spider silk to steel, scientists focus on specific strength—the ratio of tensile strength to density—where spider silk truly shines. By weight, certain spider silks can be up to five times stronger than steel, with dragline silk (used for web frames and safety lines) being particularly impressive. While steel might have higher absolute strength in larger quantities, spider silk’s strength-to-weight ratio makes it dramatically more efficient as a structural material. The tensile strength of dragline silk can reach up to 1.75 gigapascals compared to approximately 1.5 gigapascals for high-grade steel, yet spider silk is roughly five times lighter. Additionally, spider silk demonstrates remarkable toughness—the ability to absorb energy before breaking—exceeding steel by orders of magnitude in this crucial performance metric.

The Secret Behind Spider Silk’s Elasticity

Unlike steel, which becomes permanently deformed after stretching beyond its elastic limit, spider silk possesses extraordinary elasticity that complements its strength. Certain types of spider silk can stretch up to 40% of their length before breaking, compared to high-tensile steel’s mere 2% elastic limit. This elasticity comes from the amorphous regions in the silk protein structure, which can unfold and extend when tension is applied, then return to their original state when relaxed. The molecular architecture resembles a series of springs and rigid segments working in concert, allowing the silk to absorb tremendous energy from impacts. This combination of strength and elasticity explains why spider webs can capture fast-flying insects without breaking, instead dampening the energy of impact through controlled deformation.

Not All Spider Silks Are Created Equal

The term “spider silk” actually encompasses a diverse family of materials with specialized properties. A single orb-weaving spider can produce up to seven different types of silk from various specialized glands, each optimized for different functions in web construction and survival. Dragline silk, used for the web’s frame and the spider’s lifeline, offers the highest tensile strength. Capture spiral silk, which forms the sticky spiral of an orb web, prioritizes extreme elasticity to absorb the energy of flying insects. Egg sac silk provides protection with dense, tough fibers that resist environmental damage and predators. Attachment silk creates the strong connection points where webs attach to surfaces, featuring specialized adhesive properties. This natural specialization has evolved over 400 million years, resulting in a toolkit of materials perfectly adapted to specific functions.

Spider Silk’s Remarkable Environmental Adaptability

One of spider silk’s most impressive qualities is its environmental adaptability, maintaining performance across conditions that would compromise synthetic materials. Spider silk remains functional across a wide temperature range, from below freezing to well above 100°F (38°C), without becoming brittle or losing significant strength. Unlike steel, which corrodes in humid environments, spider silk performs exceptionally well in high humidity—actually increasing in strength as it absorbs water molecules that reinforce its hydrogen bonding network. The material also demonstrates remarkable resistance to bacterial and fungal degradation through antimicrobial peptides incorporated into some silk varieties. These resilient properties make spider silk particularly interesting for applications in extreme environments or medical uses where material stability is crucial.

The Challenge of Mass Production

Despite its extraordinary properties, harnessing spider silk for industrial use presents significant challenges that have limited commercial application. Unlike silkworms that can be farmed in close quarters, spiders are territorial and cannibalistic, making traditional farming approaches impractical—early attempts to create spider silk farms resulted in diminishing populations and tangled, unusable webs. A single spider produces minimal quantities of silk, with researchers estimating it would take over 1,000 spiders to produce just one gram of dragline silk. The spinning process itself involves complex changes in protein conformation, pH adjustments, and precise mechanical drawing that have proven extraordinarily difficult to replicate artificially. These production challenges explain why, despite decades of research, spider silk products remain largely experimental rather than commercial.

Biotechnology Approaches to Spider Silk Production

Modern biotechnology has opened promising avenues for producing spider silk proteins without spiders through genetic engineering approaches. Companies like Bolt Threads and Spiber have successfully inserted spider silk genes into various host organisms including bacteria, yeast, plants, and even goats to produce the base proteins in scalable bioreactors. These engineered organisms effectively become living factories, producing the complex proteins that make up spider silk in quantities impossible with actual spiders. After harvesting these proteins, the challenge shifts to spinning them into fibers that mimic the properties of natural spider silk—a process requiring precise control of protein concentration, pH, ion exchange, and mechanical drawing. While not yet achieving all the properties of natural spider silk, these bio-inspired materials are steadily improving and approaching commercial viability for specialized applications.

Synthetic Spider Silk in Medical Applications

The medical field represents one of the most promising areas for spider silk applications due to its biocompatibility, strength, and flexibility. Researchers have developed experimental sutures from synthetic spider silk that combine tensile strength with elasticity, potentially reducing tissue damage and scarring compared to traditional materials. The natural antimicrobial properties of some spider silk varieties make it an intriguing material for wound dressings that could promote healing while preventing infection. In tissue engineering, spider silk scaffolds have shown promise for supporting cell growth and regeneration, with early experiments demonstrating successful nerve cell attachment and growth along silk fibers. Perhaps most ambitious are efforts to create artificial tendons and ligaments from spider silk materials, leveraging the material’s mechanical properties that closely match these natural tissues.

Spider Silk in High-Performance Textiles

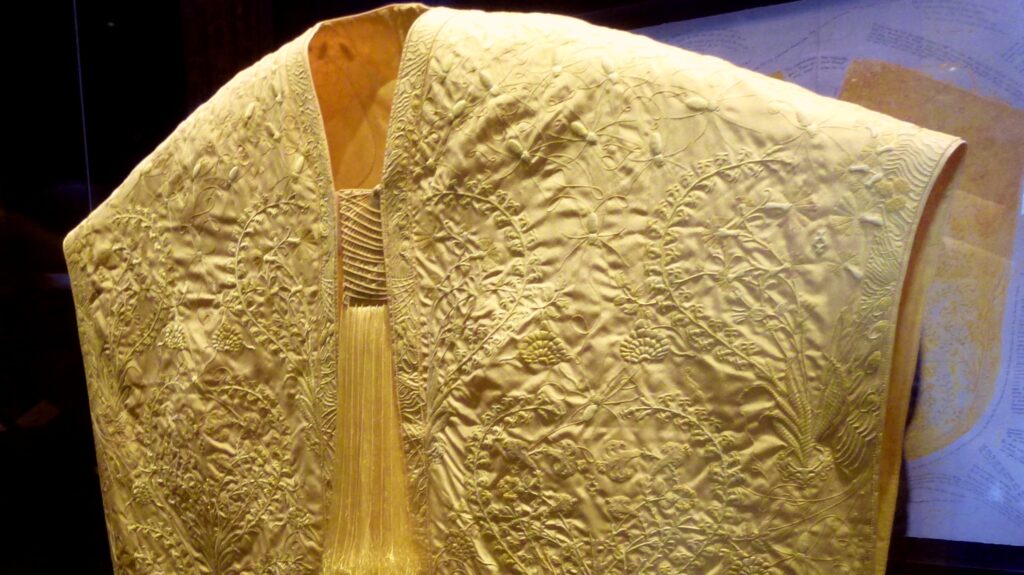

The textiles industry represents a natural application for spider silk technology, with several companies working toward commercial products that harness its unique properties. Prototype garments have demonstrated spider silk’s potential for creating ultra-lightweight yet highly durable fabrics that could revolutionize outdoor and athletic wear. Beyond basic clothing, specialized applications include potential ballistic protection in the form of spider silk-enhanced body armor that could provide better flexibility and comfort than current Kevlar-based solutions while maintaining protective capabilities. Performance athletic wear could benefit from spider silk’s combination of breathability, strength, and elasticity to create next-generation compression garments. Several companies have already produced limited-edition spider silk neckties and hats as proof-of-concept products, though at currently prohibitive costs that limit mass-market potential.

Aerospace and Engineering Applications

The aerospace industry has shown particular interest in spider silk materials due to their exceptional strength-to-weight ratio, which could dramatically reduce aircraft weight while maintaining structural integrity. Theoretical applications include spider silk-reinforced composites for aircraft components, potentially reducing fuel consumption through significant weight savings. The material’s vibration-dampening properties make it interesting for applications requiring noise reduction or stability, such as helicopter blades or sensitive instrumentation mounts. Researchers have also explored spider silk’s potential in flexible electronics, where its strength and elasticity could enable components that bend without breaking. NASA has funded research into space applications, including potential use in parachutes for planetary exploration missions where the material’s combination of low weight and high strength would provide significant advantages over current synthetic materials.

Learning from Spider Silk: Biomimetic Materials

Beyond direct replication of spider silk, scientists are developing new materials inspired by its structural principles through the field of biomimetics. Researchers have created synthetic polymers that mimic the beta-sheet nanocrystal structures found in spider silk, resulting in new materials with enhanced mechanical properties without using actual silk proteins. 3D printing technologies have enabled the creation of structures that mimic the layered, multidirectional fiber arrangement of spider webs, providing insights for architectural and engineering designs. The molecular folding patterns of silk proteins have inspired new approaches to protein engineering and self-assembling materials with applications ranging from drug delivery to electronics. Even when perfect replication remains challenging, understanding the fundamental principles behind spider silk’s remarkable properties continues to drive innovation across materials science.

Environmental and Sustainability Benefits

Spider silk production represents a potentially sustainable alternative to petroleum-based synthetic fibers that dominate current materials markets. Unlike traditional synthetic fiber production that relies on fossil fuels and generates significant pollution, bioengineered spider silk proteins can be produced using renewable resources and fermentation processes with substantially lower environmental impacts. The biodegradability of protein-based fibers addresses growing concerns about microplastic pollution from conventional synthetic textiles that persist in the environment for centuries. Production methods using genetically modified organisms in contained bioreactors require minimal land use compared to traditional fiber crops like cotton, potentially reducing agricultural pressure on natural ecosystems. As industries face increasing pressure to reduce environmental footprints, spider silk technologies offer a promising direction for next-generation materials that combine performance with sustainability.

The Future of Spider Silk Technology

As research continues, the gap between natural spider silk and synthetic alternatives continues to narrow, with several promising developments on the horizon. Advances in genetic engineering, including CRISPR technology, are enabling more precise control over protein expression in host organisms, potentially improving yield and consistency of synthetic spider silk proteins. Computational modeling of protein folding and material properties is accelerating development by allowing researchers to predict how modifications will affect performance before undertaking costly experiments. Hybrid approaches combining biological production of proteins with engineered spinning processes offer paths to overcome current limitations in replicating the complex natural spinning process. While challenges remain, the continued convergence of biotechnology, materials science, and engineering suggests that practical, scalable spider silk applications may finally be within reach after decades of research.

Conclusion: Nature’s Engineering Marvel

Spider silk stands as one of nature’s most extraordinary engineering achievements—a material that combines seemingly contradictory properties of strength and flexibility through elegant molecular design refined over millions of years of evolution. While we’ve made remarkable progress in understanding and beginning to replicate this exceptional material, much remains to be discovered and developed before spider silk technologies reach their full potential. The journey from natural inspiration to practical application highlights both the genius of natural design and the challenges of mimicking complex biological systems. As research continues and production challenges are gradually overcome, spider silk technologies may eventually fulfill their promise of revolutionary, sustainable materials that transform industries from medicine to aerospace. Nature’s humble spider may yet teach us our most important lessons in material design, offering solutions to human challenges through one of the most ancient and refined technologies on our planet.